全自动集尘器

-

≥ 1台¥3850.00

全自动集尘器

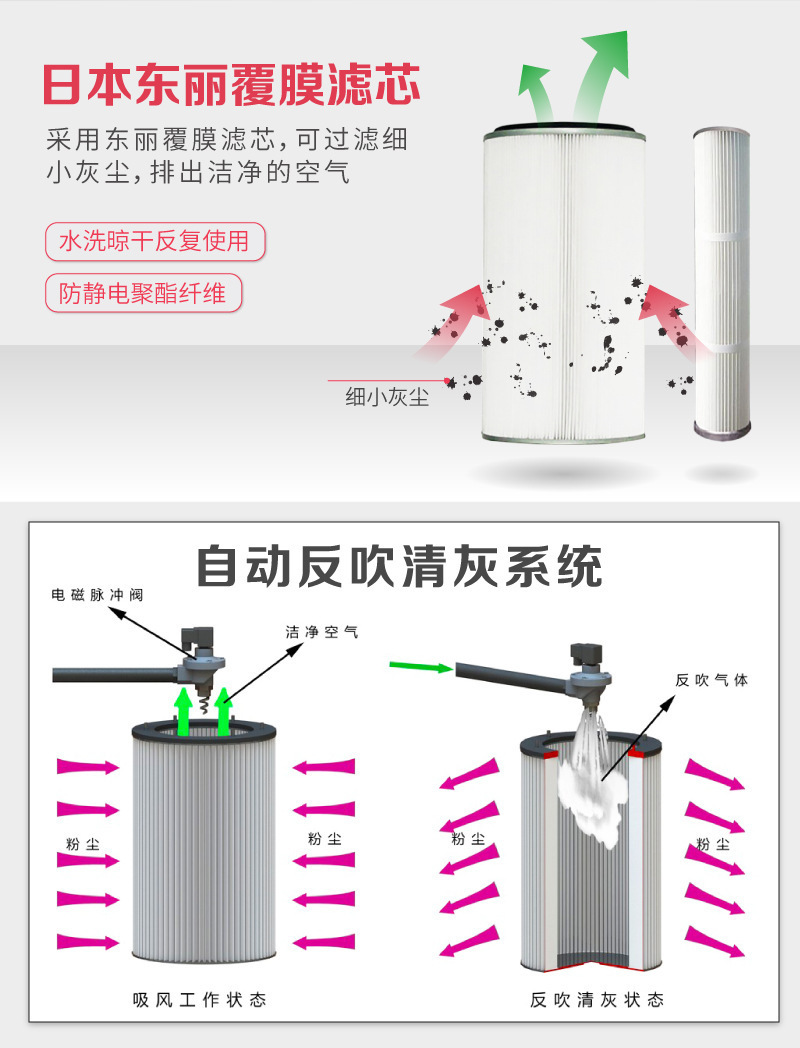

传统的工业吸尘器的过滤袋一般无法清洁极其细微的粉尘颗粒,这些粉尘颗粒由排气口重新回到车间里,二次污染了车间的环境。中央集尘系统的主机部分一般固定在车间外的主机房内,且过滤材料选用进口基材的覆膜滤筒,通过此种过滤装置,清洁后可将粉尘颗粒降至< 0.3μm,车间里无粉尘异味,创造更为清洁的车间环境。

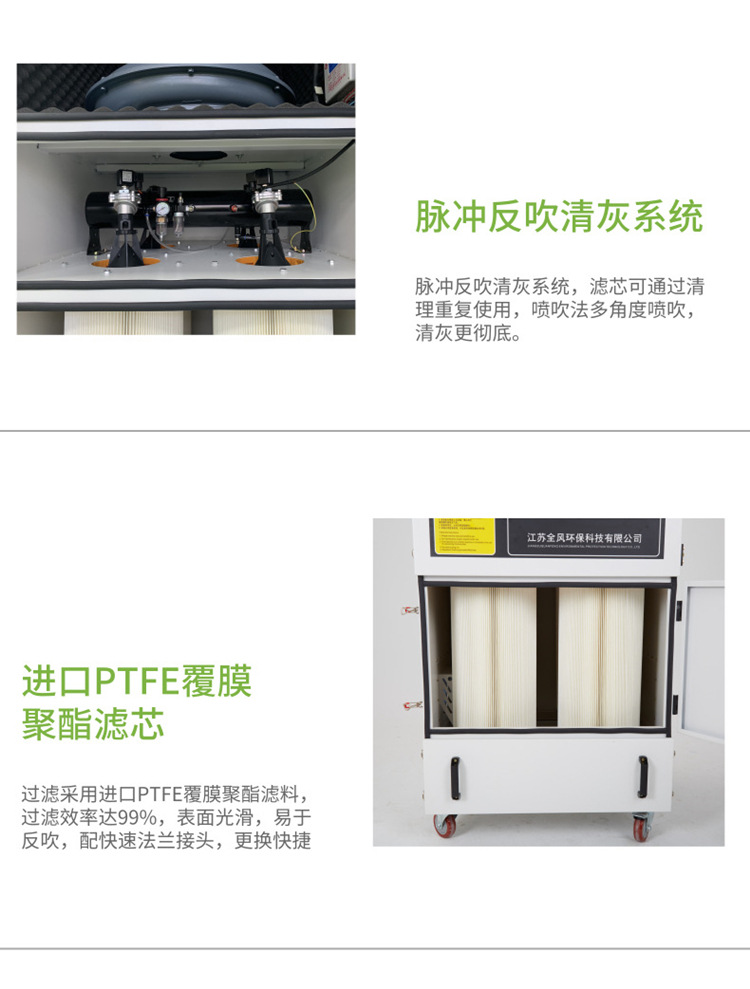

一、滤筒结构及其特性

1、刚性滤料成折叠式均匀分布组成滤筒,使其具有***小的体积,发挥***大的过滤面积效应。

2、在普通滤料的外层,再覆盖一层超细纤维层,从而使过滤效果有了本质的提高。被过滤粉尘仅停留在滤料超细纤维层的外表,所以大大减少了过滤阻力,节省耗电30%以上,节能效果显著,并且清灰十分。同时也解决了超细粉尘、纤维性粉尘难以处理等各类难题。

3、选用PTFE覆膜滤料适用于潮湿的含尘气体,由于滤料与水的接触角大于108度,使得附着于滤料表面的潮湿粉尘不粘滤料,极易吹落,因而,解决了潮湿粉尘结露粘料的问题。

4、过滤效率:普通滤料为5μm以上粒径粉尘收集能力为99.9%,覆膜滤料为0.5μm以上粒径粉尘收集能力为99.9%。

5、普通滤筒的正常使用温度为80℃(如订货时加以说明,使用温度可达130℃)。

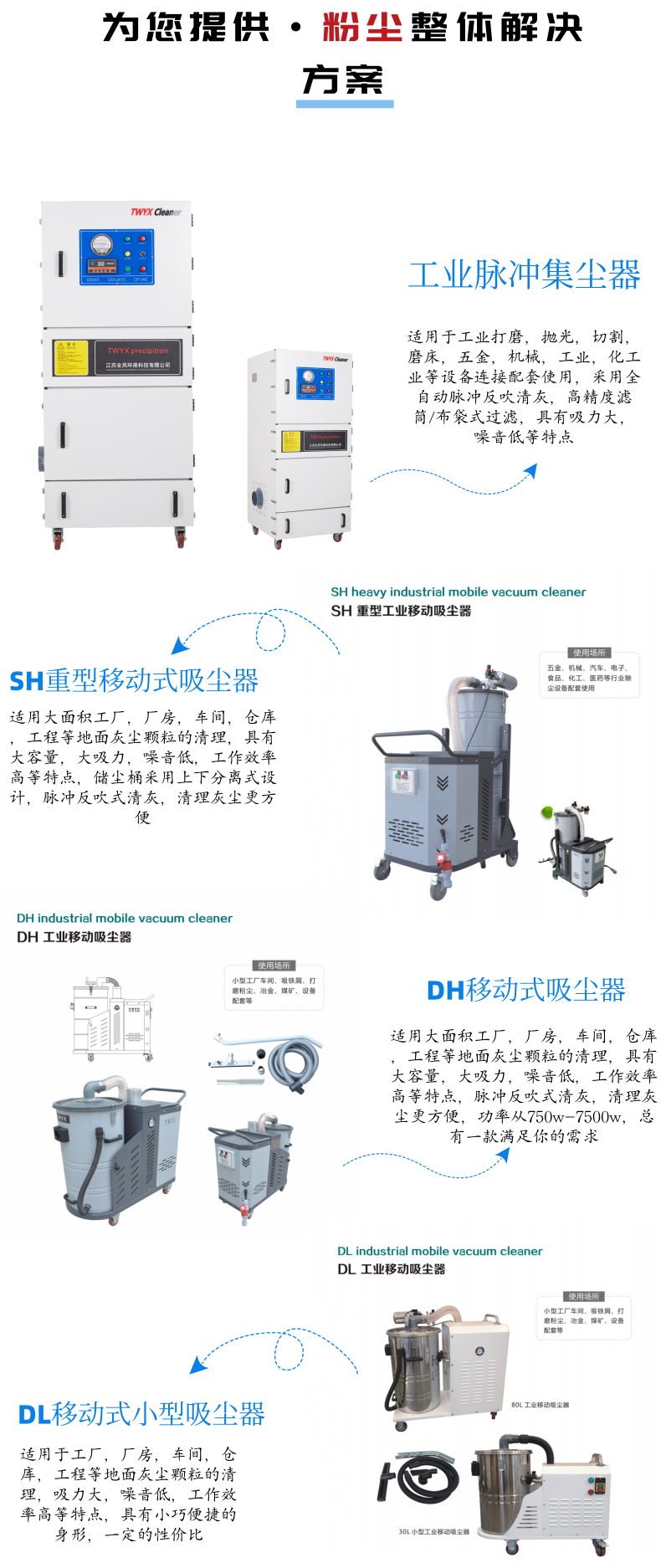

The absorption of dust in the process of packaging, cleaning work, improve the working environment of workers, suitable for: chemical plant, food workshop, machinery workshop and other ultrafine powder, dust, ash, such as flour, starch, silica gel powder, graphite, carbon black, metal powder, cement powder, ceramic powder.

The filter element made of different substrates is not the same as the filter scheme, industrial dust collector industrial vacuum cleaner manufacturers: Pulse backblowing automatic dust collector, manual shock dust cleaner, mobile vacuum cleaner, strong high pressure vacuum cleaner, fixed vacuum cleaner, explosion-proof vacuum cleaner, industrial vacuum cleaner, bag vacuum cleaner, DC vacuum cleaner, industrial dust collector, dust blower, dust blower and so on!

全自动集尘器

作为一种除尘设备,目前已广泛应于各工业部门。近年来,随着国民经济的发展以及愈来愈严格的环境保护要求,高压除尘器在产量上有了相当大的增长,品种也日渐增多。因此,在设计工作中合理地选定磨床集尘设备的基本参数,正确地进行除尘系统设计,不仅对于控制污染、保护环境有重要作用,而且对于提高设备处理含尘气体的能力,降低设备投资从而减少工程造价,也具有极重要的经济意义。

Flexible move into any position of the factory, not bound by hair dust spots are not fixed, industrial dust particle collector mobile welding smoke purifier is used for welding, polishing, cutting, grinding process such as smoke and dust purification and recycling of rare metals, precious materials, etc., can purify large amounts of suspended in harmful to human body small metallic particles in the air.

Because the enterprise"s production space is clean degree directly affect the quality of its products, and even affect the product percent of pass, to reduce the cost, can be regular cleaning of equipment (surface and corner),