新型消防箱自动成型机消火栓箱一次成型设备消防栓箱自动生产设备冷弯成型机厂家

-

≥ 1套¥196000.00

新型消防箱自动成型机 消火栓箱一次成型设备 消防栓箱自动生产设备 冷弯成型机设备厂家

潍坊炜桦冷弯机械制造有限公司公司本着以“生产、诚信经营、质量为本”的管理理念,汇集了一批国内的产品研发专才、工程技术人员和服务队伍。目前拥有中上职称20多人,经济管理人员10多人,公司拥有强大的生产团队及售后服务队伍,在国内有多个营销网点,并在省内外设立了多个办事处及售后服务网络。随着炜桦品牌度和产品美誉度的提升,近年来,公司已将产品的销售网络扩大到广西、湖南、湖北、重庆、云南、河南、河北、山东、浙江、江苏等周边十几个省、市,自治区。

Weifang Weihua Cold Bending Machinery Manufacturing Co., Ltd. in line with the management concept of "professional production, honest management, quality-oriented", has gathered a number of domestic product research and development expertise, engineers and technicians and service teams. At present, the company has more than 20 middle and upper titles, more than 10 economic managers, a strong production team and after-sales service team, a number of marketing outlets in China, and has set up a number of offices and after-sales service network both inside and outside the province. With the promotion of brand awareness and product reputation of Weibi, in recent years, the company has expanded its sales network to more than a dozen surrounding provinces, cities and autonomous regions, such as Guangxi, Hunan, Hubei, Chongqing, Yunnan, Henan, Hebei, Shandong, Zhejiang, Jiangsu and so on.

炜桦冷弯机械生产配电箱,消防箱流水线设备厂家,配电箱,消防箱流水线设备操作系统为全自动智能程序操作控制系统,整条流水线只需一个工人操作即可替代传统工艺生产配电箱,消防箱10个工人的工作量,既降低了箱体的生产成本,又提高了配电箱的的生产质量,为企业在现代化市场经济的浪潮中奠定基石。传统工艺生产配电箱,厂家都是使用板料生产箱体,这样就会造成对于成品板料计算不到位,造成板料的浪费,就算是使用激光切割也会有料边浪费情况出现,而且生产效率提升不上去,造成传统工艺生产配电箱难以做大做强。即使做大了企业的用工成本,管理成本成倍增加,造成难管理,没利润的情况出现。

Weibi cold bending machinery specializes in the production of distribution boxes, fire box assembly line equipment manufacturers, distribution boxes, fire box assembly line equipment operating system for fully automatic intelligent program operation control system, the entire assembly line can replace the traditional process of production of distribution boxes, fire box 10 workers workload, which reduces the box body. The production cost also improves the production quality of distribution boxes, laying the foundation stone for enterprises in the wave of modern market economy. Distribution boxes manufactured by traditional technology are all made of sheet metal, which will result in inadequate calculation of finished sheet metal and waste of sheet metal. Even if laser cutting is used, there will be waste of material edge, and the production efficiency can not be improved, which makes it difficult to make distribution boxes manufactured by traditional technology bigger and stronger. 。 Even if the employing cost of a larger enterprise is enlarged, the management cost doubles, resulting in difficult management and no profit.

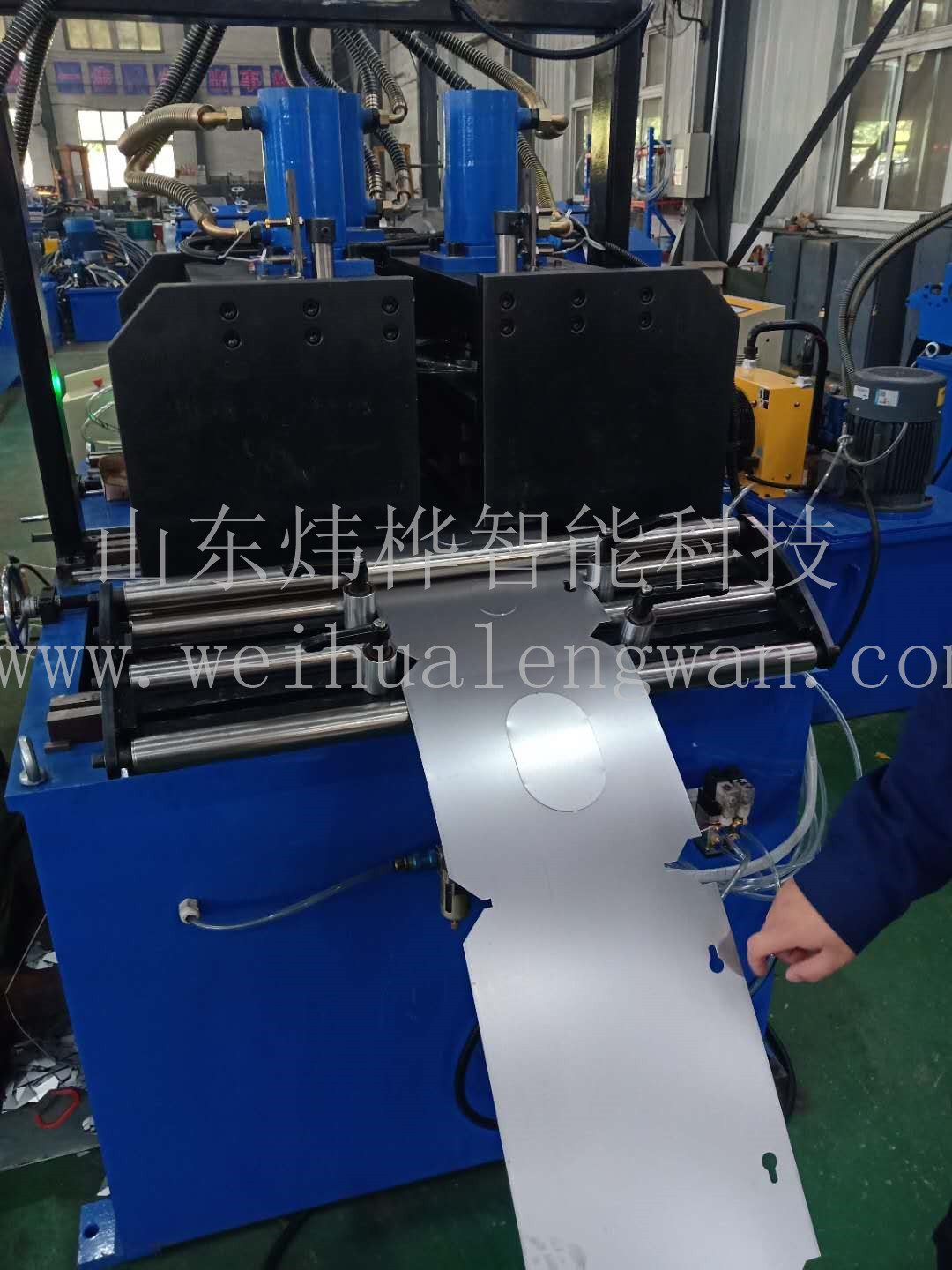

消防箱壳体生产设备,灭火器箱箱体一次成型设备,生产灭火器箱门板、盖板自动折弯生产线工艺:

Fire box shell production equipment, fire extinguisher box forming equipment, production of fire extinguisher box door plate, cover plate automatic bending production line process:

放料机—校平机—伺服送料机—冲孔部分—定尺切断部分—成型部分—自动折弯—收料台、机器人自动焊接,电气控制柜等部件组成。

The feeder-leveler-servo feeder-punching part-fixed length cutting part-forming part-automatic bending-receiving table, robot automatic welding, electrical control cabinet and other components are composed.

箱体自动折弯一次成型生产设备,消防箱箱体自动生产线主要参数:

The main parameters of the automatic production line of fire box are as follows:

材料规格:1、Q235 (钢卷) 2、不锈钢带

Material Specifications: 1, Q235 (Coil) 2, Stainless Steel Strip

钢带厚度:1.2 mm

Strip thickness: 1.2 mm

钢带宽度:≤300mm

Width of steel band: <300mm

生产速度:约100个箱体//小时

Production speed: about 100 boxes per hour

总电机功率:15kw

Total motor power: 15 KW