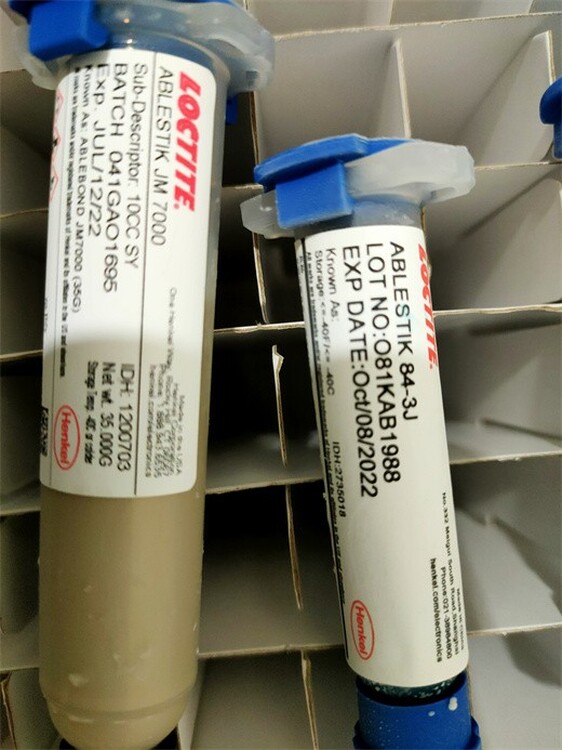

白城电子材料汉高ABLESTIKJM7000导电胶,乐泰导电胶

-

面议

LOCTITE ABLESTIK JM 7000 die attach adhesive has been

formulated for use in high throughput die attach applications. This

material has been used successfully on rigid substrates with die sizes

up to 700 mils.

LOCTITE ABLESTIK JM 7000 has been approved by DESC and

Rome Laboratory for military products.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Viscosity, HAAKE RV-20 Rotoviscometer, mPa·s (cP):

Cone 1º @ Shear rate 22 s

-1 9,000

Work Life @ 25°C, hours 8 to 16

Shelf Life @ -40°C (from date of manufacture), days 365

TYPICAL CURING PERFORMANCE

Cure Schedule

30 minutes @ 150°C

Suggested temperature cures are from 150 to 350ºC. For

applications requiring higher electrical conductivity, a cure cycle of 15

minutes @ 300ºC is recommended. Product properties will not be

reduced by subsequent post die attach thermal exposure, i.e.,

wirebond, and/or lid seal up to 370ºC.

TYPICAL PROPERTIES OF CURED MATERIAL

Physical Properties

Coefficient of Thermal Expansion, :

Below Tg, ppm/°C 33

Glass Transition Temperature (Tg) by TMA, °C 240

Bulk Thermal Conductivity, W/(m-K):

@ 90°C 1.1

@ 165°C 1.0

Tensile Modulus, DMTA :

Cured 30 minutes @ 300ºC N/mm² 10,000

(psi) (1,450,377)

Extractable Ionic Content, @ 100°C:

Chloride (Cl-) <10

Sodium (Na+) <15

Potassium (K+) <15

Decomposition (in N2):

TGA analysis @ 10ºC/ minute ramp from 25 to 400

ºC

@ 340ºC, % 0.2

@ 400ºC, % 0.3

Electrical Properties

Sample cured 30 minutes @ 300ºC

Volume Resistivity, ohm-cm ≤0.01