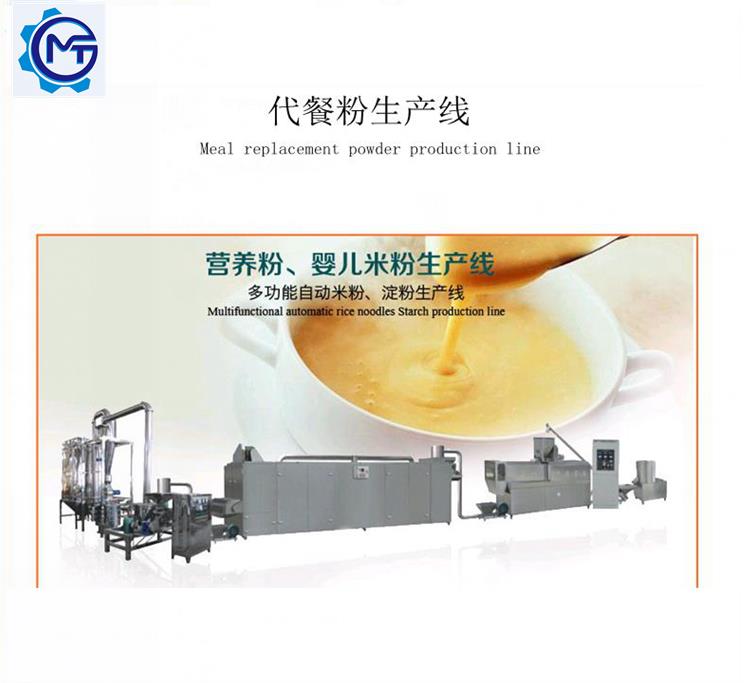

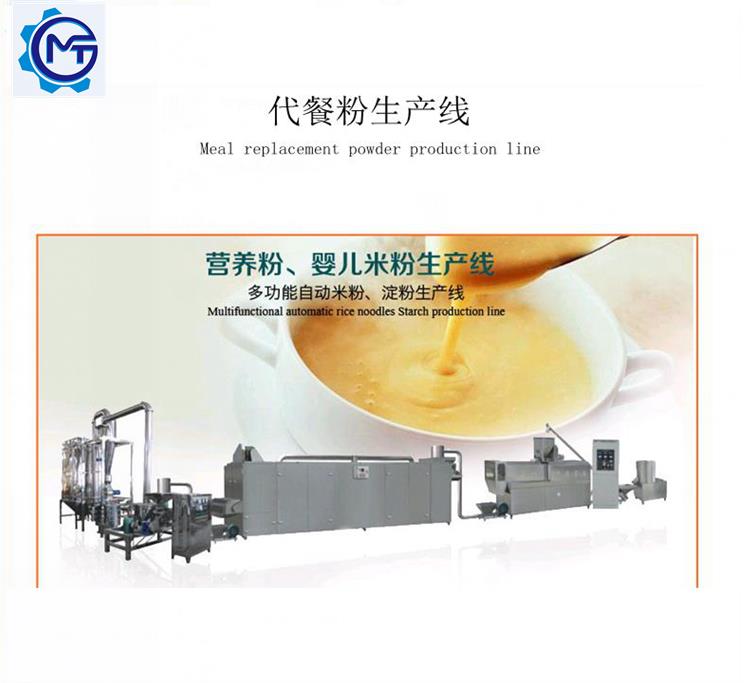

紫薯魔芋饱腹EW冲泡型速溶粉 代餐粉生产线加工机器服务 MEIT即食冲泡营养粉 速溶粉生产线设备制造厂家 五谷黑芝麻糊JHH代餐粉 营养粉生产线机器设备厂商 MT品质芝麻糊薏米 营养粉 速溶粉加工设备 SE65 冲泡型营养粉设备 速溶粉生产线厂家售后保障 河南PU65冲泡营养粉 代餐粉生产线加工设备服务至上 山东五谷杂粮ET65速溶代餐粉生产线 营养粉机器提供商 河北供应JK65营养粉设备 代餐粉生产线厂商 营养粉生产线 代餐粉设备 营养粉生产设备 代餐粉设备 谷物代餐粉生产线

Mixing method: According to the number of the formula, put the raw materials and the nutritive fortifier (add vitamin B127 grams, calcium 6.5 grams, lysine 1 gram per 500 grams) into the mixer to fully mix, and add some warm water and a little salt (0.2%), and then stir fully, so that the moisture content of the dough is 35~37%.Pelleting: The dough is pressed into a wide strip by a roller pelleting machine and sent to a pelleting machine with a hollow mould in the shape of rice grains (there are many kinds of rollers and extruders). The long diameter of the hollow mould in the roller pelleting machine is 0.8cm and the short diameter is 0.3cm.Extruding granulator is basically the same as spiral macaroni extrusion molding machine. After extrusion, the material is extruded from the mold hole and formed, but the technological parameters are complex and the technical requirements are high.) Under the state of pressure, the surface strip is pressed into rice grains, and then the rice grains are separated and screened by the separator to remove the powder.Cooking: About 40% of the rice grains with water are steamed on the conveyor belt for 3~5 minutes, so that the rice grains form a protective film and kill pests and microorganisms.Drying: The drying temperature is generally 95℃, and the drying time is about 40 minutes.After drying, the moisture of artificial rice should be reduced to about 13%, and then cooled down to 11~11.5%, which can be stored for consumption.The product features artificial rice weight 1428~1432 grams per liter, specific gravity is 1.35, hardness 6.0, similar to natural rice, and dip resistant, can withstand rubbing, color, flavor, aroma are similar to natural rice.If mixed with natural rice, the effect is better.Company profile: Jinan Meiteng machinery Equipment Co., Ltd. is a professional food machinery research and development, design, manufacturing, sales, engineering, service as one of the manufacturers.Since its establishment, specializing in the manufacture of puffing machinery and the technical development of food machinery, all for the purpose of customer interests to create a good reputation in the majority of customer groups.Company products include extrusion machine, puffed food production line, cereal production line, the macaroni equipment, Italy face to face with production line, the purple potato starch production line, baby rice noodle production line, noodle production line, Fried noodle production line, the rice crust equipment, bugles production line, the salad bar equipment, triangular piece of doritos production line, Fried Mimi shrimp production lines, Fried millet production lines, artificial meat processing equipment, breadcrumbs production line, equipment, material-starch breakfast cereal grain production line, the sandwich meters fruit production line, the wheat burn food equipment, spiral shells/extrusion Fried food production line, the modified starch production line, the potato starch production line,Binder type coal production line, the steam of oatmeal tablet machine, artificial rice production line, the dog food equipment, dog food, dog bites rubber production line, the wet fish feed production, aquaculture feed equipment company with the industry elite senior talent and technology advantage, combined with their own "pragmatic, innovative and enterprising, take honestly as this," business philosophy, to "serious, active, strict and efficient" style of doing things, to provide customers with high quality products.The company with strong technical strength, high quality products, reasonable price, perfect sales后服务,愿真诚与您合作,共创未来。

生产线:印度、泰国、印尼、东欧、南非、马来西亚、印度尼西亚、巴基斯坦、东南亚、中东等等众多国家和地区,深受客户的好评。

营业执照经营范围:

食品机械、包装机械、饲料生产设备、塑料加工设备、建筑机械设备(不含特种设备)的技术开发、生产、销售、技术服务;进出口业务服务,建材的批发零售(依法须经批准的项目,经相关部门批准后方可开展经营活动)

系列烤箱说明:

本系列烤箱适用范围广,可对条状、块状、粒状等膨化食品或其他物料干燥,用户可根据要求选用不同层数,不同长度,不同热源的烘干箱。整体设计紧凑,合理,操作方便。传动采用双节距滚子链传动,往返式烘干,运转平稳,绝无卡阻现象。干燥温度,时间可调,烘干效果。配备节能燃烧系统,热源分配合理,受热均匀、能耗低、产量大。

休闲食品厂设备,西餐店设备,茶餐,厅设备,调料加工厂设备,果蔬加工厂设,饮品店设备,中餐店设备,肉制品加工厂设备 ,其他

soaking rice, low-temperature frying, grinding, mixing and packaging, etc. The product aroma was rich, and there would be a little precipitation during flushing and adjustment, so there was a high requirement for grinding fineness.;Expansion drying method: grain crushing, grain raw material mixing, extrusion, crushing, various grain raw material nutrition composition mixing, packaging.This kind of products is mainly used for processing various kinds of nutritive grain powder, old nutrition powder and other products. The processing technology is relatively complicated and perfect compared with the frying technology, and the products have good taste and good blanking effect. At present, the products have a relatively large market

固体饮料生产线

1、产品简介;固体饮料是指以谷物为主要原料(玉米、大米、小米、面粉等),以蔬菜、水果、蛋类、肉类等选择性配料,加入钙、磷、铁等矿物质及维生素等通过挤压膨化工艺使谷物淀粉糊化,蛋白质熟化,加工成一种食用方便、口味浓香、营养的新时代营养补充食品。统称称为固体饮料或代餐营养粉

工艺介绍:固饮料的主要加工工艺分为低温醅烤工艺和挤压膨化工艺;低温醅烤工艺为:泡米、低温炒制、粉碎、混合、包装等,产品香味浓郁,冲调时会产生少许沉淀,对粉碎细度要求较高。;膨化干燥法:谷物粉碎、谷物原料混料、挤压膨化、粉碎、各种谷物原料营养成分混合、包装。膨化生产工艺,产品以粉末状为主,该类产品主要用于加工各种营养谷物粉,老年营养粉等产品,加工工艺相对炒制工艺复杂、工艺完善,产品口感好,冲调效果好,目前有较大部分市场

2、膨化生产线介绍;本产品生产线根据生产产量和原料性质、可分为小型、中型、大型等生产线,生产线加工产品根据所需产品定位,配置不同方案的生产线。由于经济增长和技术不断升级的原因,食品生产厂家多采用自动化比较高的生产线配置。

3、膨化生产线流程:原料粉碎→ 混合→ 挤压膨化→ 烘干→ 二次粉碎→ 二次混合→储料→包装→成品入库

4、设备配置:因客户需求不同,会根据生产要求合理配置生产加工方案

产品说明

生产工艺流程图:

技术参数

型 号 | MT65-II型生产线 | MT70-II型生产线 | MT85-II型生产线 |

总装容量 | 86.35kw | 90.75kw | 121.06kw |

实耗功率 | 55kw | 57kw | 85kw |

生产能力 | 100~160㎏/h | 150~200㎏/h | 200~350㎏/h |

外形尺寸 | 35000×2000×2600mm | 36500×2000×2600mm | 41200×2000×2800mm |

产品图片

代餐粉是一种由谷类、薯类食材等为主,其它属类植物的根、茎、果实等可食用部分为辅制成的一种单一或综合性冲调粉剂产品。它集营养均衡、效果显著、食用方便等优点于一身。

代餐粉自身均衡的营养,吃了以后不会饿,并且可以基础的营养需求,完全可以不再吃饭。在实际的使用中,可以根据自己想要的减肥速度,选择代一餐或是二餐,在代餐的选择上,代晚上效果是好的,如果是选择一餐,好是选择代晚餐,如果想快速的减肥,可以选择代早餐+晚餐,或是中餐+晚餐,使用代餐粉可以很好的控制饮食热量,同时补充全面的营养,起到健康减肥的作用。

种类:果蔬代餐粉、蛋白复合粉、谷类代餐粉、膳食纤维粉等。