三相380v去毛刺打磨集尘器

-

≥ 1台¥3850.00

三相380v去毛刺打磨集尘器

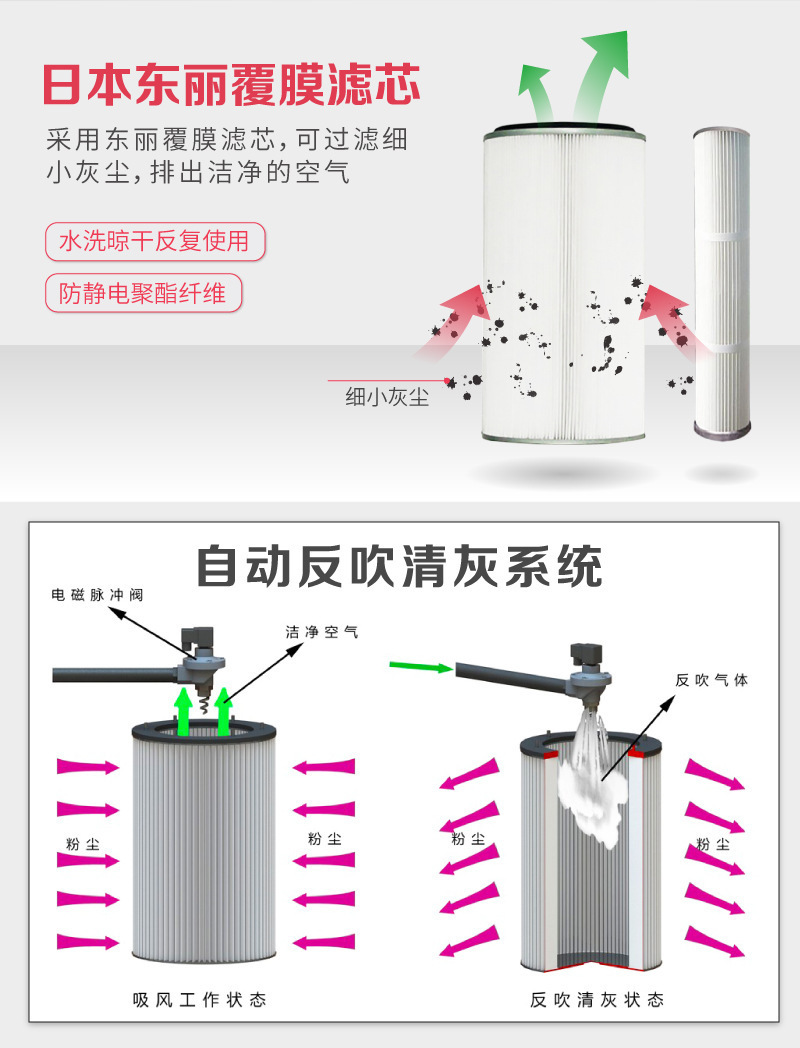

工作原理:依靠磨床集尘器鼓风机大吸力的特性,滤芯采用聚四氟乙烯覆膜多微孔材料,具有防水、防油、耐高温等特点,加装隔离装置,通过管道将鼓风机与磨床工作平台相连,靠吸力吸附粉尘或碎屑,包装过程中产生粉尘的吸收、清净工作,改善工人的作业环境,当通过隔离装置的精密型过滤器过滤处理后,粉尘就会被收集到过滤集尘柜,另一出风口就会排出清新的空气。能有效处理钢铁、非铁金属、矿业、各种炉用除尘(化铁炉、溶解炉、焚化炉)。

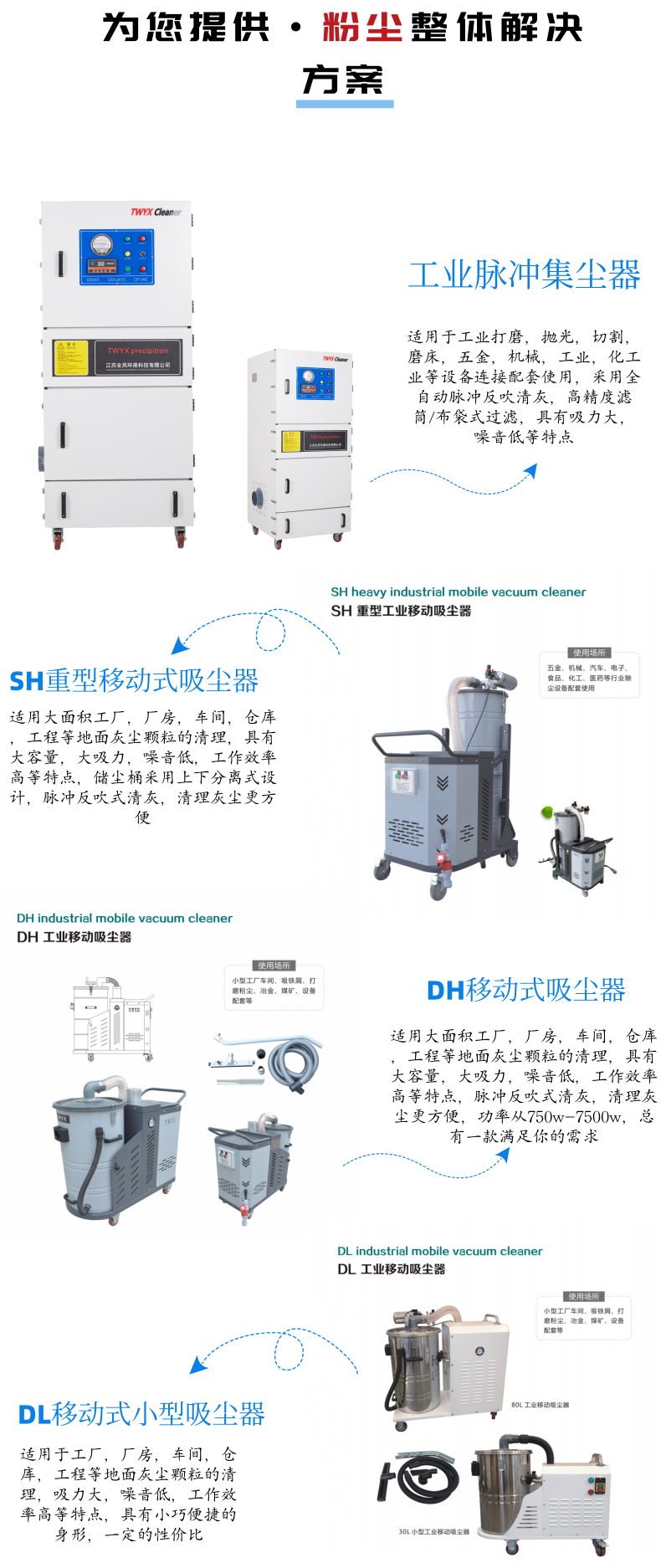

在吸一些较重的颗粒时,须考虑接管管径及管长度,通常影响吸力效果的一些主要因素有,可全天候 24小时不停运作,配套各种精密机械,作业于机台设备的清洁打扫,管径太粗、管径长度太长、吸风机本身功率太小、弯道所接太多且分级处理不好!

选购吸尘机当以质量可靠、功能使用、操作方便为参考依靠、工业吸尘器大量应用于纺织、化工、机械、医药、铸造等各个领域,除了要了解结构与功率外,还要考虑附加功能的多少。

Fans are widely used in grinding worktable to absorb dust particles, large-area dust collection in workshop, etc; At the same time, it is applied to the on-site collection of dry high concentration dust and crushed materials produced in powder absorption, metallurgy, machinery, building materials, ceramics, plastics, chemical industry, medicine, tobacco and other industries. It is especially suitable for the filtration of fine and fine powder dust produced in the process of crushing, feeding, mixing, filling, metering, loading and other operations, as well as the recovery of precious metal particles and high value-added material dust.

三相380v去毛刺打磨集尘器

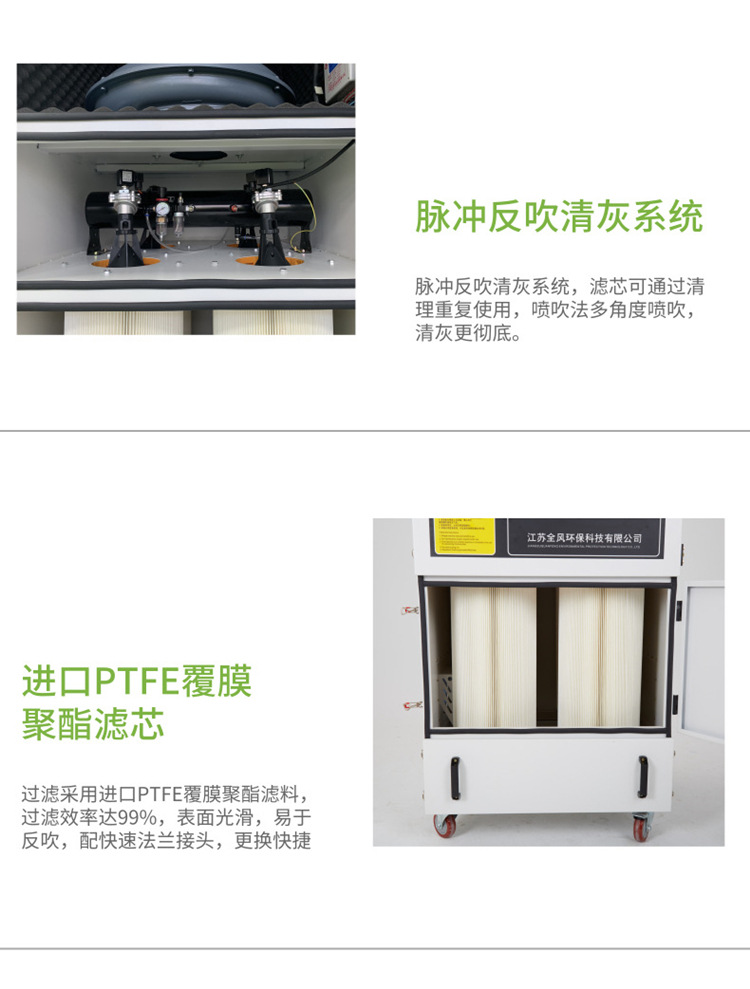

在抛光、切割、打磨、粉碎、焚烧(燃烧)、等工业生产过程中,产生碎屑、烟雾、或者粉尘等微细颗粒物,用于工业生产过程中收集废弃物、过滤和净化空气、进行环境中粉尘及颗粒的清扫,通过除尘设备把这些微细颗粒物从气体中分离出来的过程为工业除尘的过程。过滤采用进口 PTFE覆膜聚酯滤料,过滤效率达99%,表面光滑,易于反吹,法兰接头更换快捷。

Is a kind of single-machine filter cartridge dust collector, for the vertical cabinet type box body structure form, and industrial vacuum cleaner because of its special function, and become a part of the production machinery can not be omitted in the pharmaceutical production enterprises.

Fans are widely used in grinding worktable to absorb dust particles, large-area dust collection in workshop, etc; At the same time, it is applied to the on-site collection of dry high concentration dust and crushed materials produced in powder absorption, metallurgy, machinery, building materials, ceramics, plastics, chemical industry, medicine, tobacco and other industries. It is especially suitable for the filtration of fine and fine powder dust produced in the process of crushing, feeding, mixing, filling, metering, loading and other operations, as well as the recovery of precious metal particles and high value-added material dust.