叠片机配套工业除尘器工业集尘器

-

≥ 1台¥3850.00

叠片机配套工业除尘器 工业集尘器

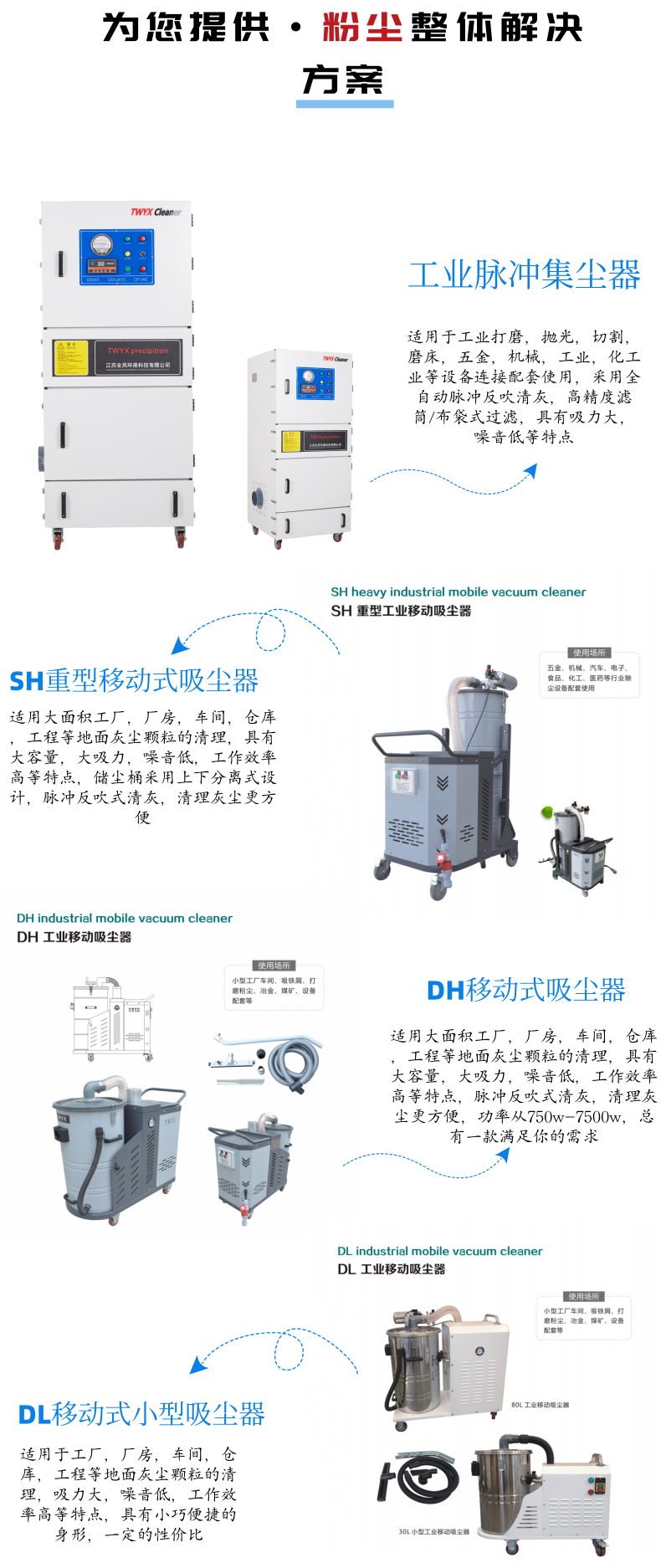

工业吸尘器风机采用 380V高负压旋涡风机,外壳和枫叶均采用铝合金材质压铸成型。叶轮为L行设计可以增加它的真空度和风量,术语来理解的话就是真空度就是压力大可以吸取重颗粒物的垃圾,风量大就是吸尘速度快工作效率的意思。风机的转子和垫子矽钢片采用纯铜线制作非常,配有NSK耐高温轴承和单的风冷式排热风扇,风机在运转时可以同时启动排热风扇保持风机一直在常温下进行作业。无油,无碳刷免维护设计可以长时间不停机运行不会高温使用时间更久。

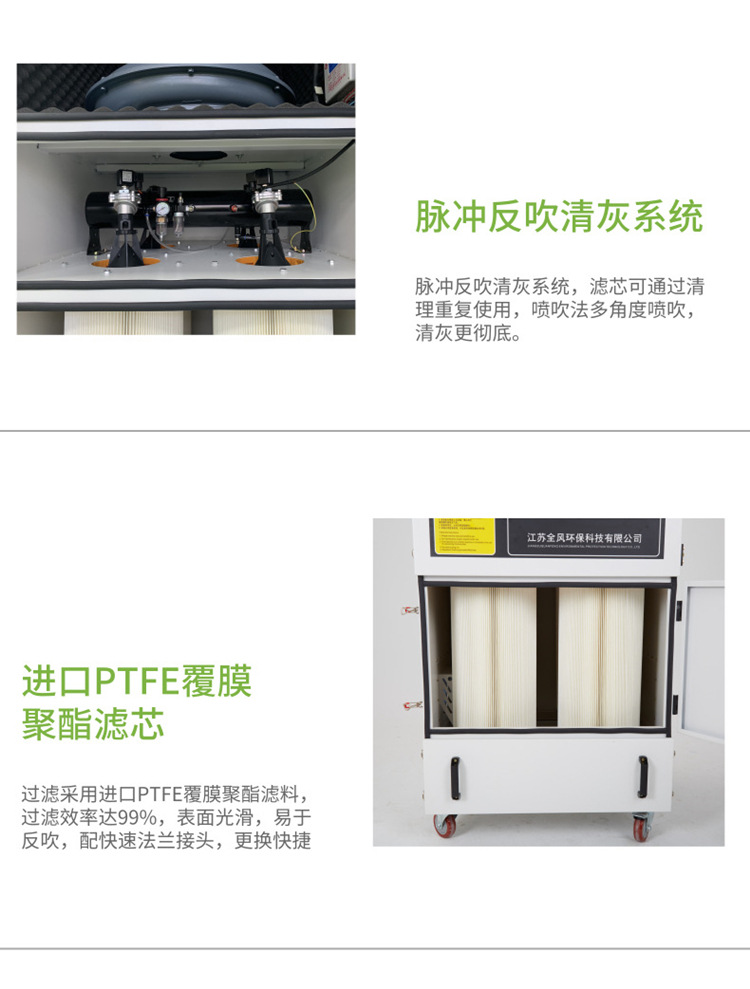

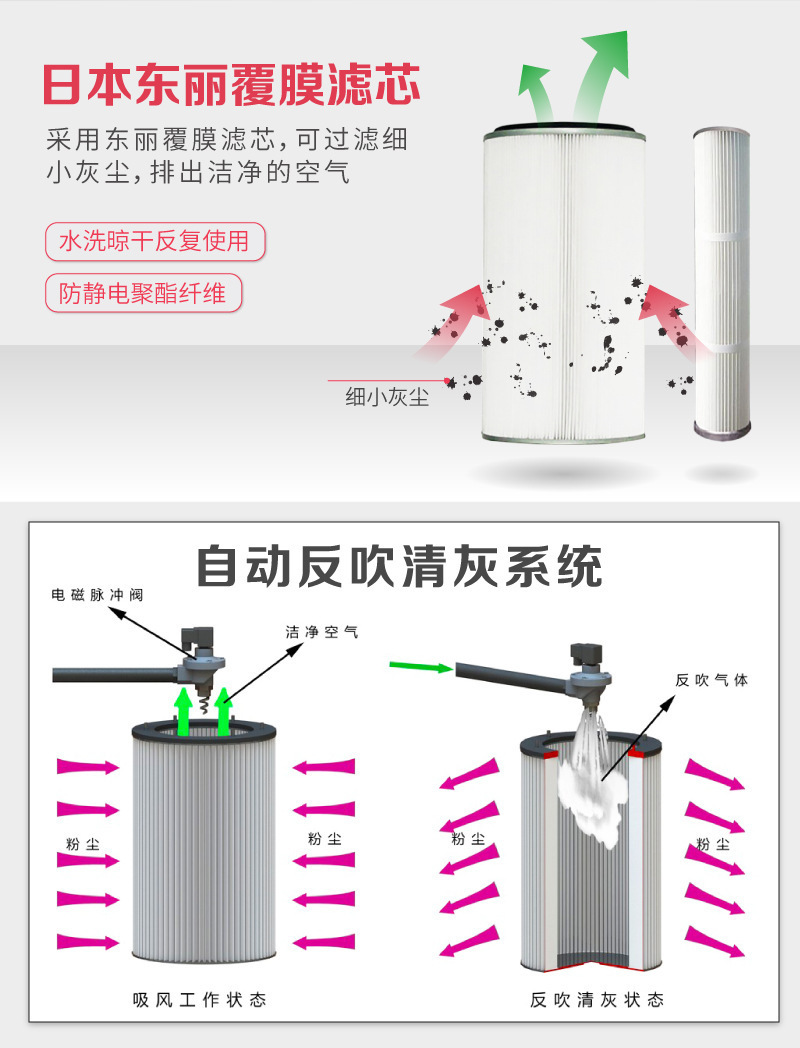

我公司推出的小型化滤筒式集尘机,产品采用韩国*的率风叶,搭配西门子贝得的电机,具有风量大,振动小,噪音小等特点;滤芯采用日本东丽的滤料,过滤精度高,寿命长;通过时间控制器控制电磁脉冲阀进行清灰,清灰效果好,日常使用不需工人频繁清灰,避免二次污染的产生;设备安装活动脚轮,方便不同工位使用,节省空间。

The vertical combined structure is adopted, which is composed of push-pull drawer type dust storage, filter cartridge dust removal, pulse jet dust removal and air outlet. The dust collection effect is 99.5% in an economic way. The modular combined design can be determined according to the user space. The power of the dust collector ranges from 0.75 kW to 22 kW. It is equipped with a secondary filtration system. The advanced plunger explosion back cleaning system is applied to optimize the back cleaning and a variety of filter materials, It can be applied to the collection of various smoke and dust.

叠片机配套工业除尘器 工业集尘器

集尘器原理 :通过工业风机、漩涡风机、漩涡气泵等设备将桶身内部抽成真空,使其负压升高,高负压使空气迅速通过进风口流入桶身内部,桶过吸尘刷及吸尘管,流动的空气携带需要收集和处理的固体颗粒物进入桶身,过滤袋与进风口相接,固体被附着于滤袋的内表面,初过滤的空气通过过滤袋的缝隙,再经滤芯的二次过滤,可使空气达到排放的标准,过滤后的空气通过风机或气泵的排风口进入排风道, *** 终排回车间内部,以减少能量,特别是热能的损失。

负压越高,吸力越强,吸尘口的口径越宽,则流量增加,相应的负压变小,吸力变小,通过选择合适的型号,可使负压保持在一个恒定的范围之内,以适应不同的物料的吸取和处理。

Filter element using polytetrafluoron film coated porous material, dust and other fine particles, through the dust removal equipment to separate these fine particles from the gas flat process for industrial dust removal process, with waterproof, oil resistance, high temperature resistance and other characteristics, and can make the particle size of dust up to 0.1-0.5 micron.With very outstanding and efficient filtration performance. The filtered purified gas is discharged from the air outlet, which can be discharged directly in the indoor circulation, or discharged outdoors according to the need. The cylinder fold design can make the filtering area as high as 10-20 square meters.