激光雕刻全自动脉冲集尘器

-

≥ 1台¥3850.00

激光雕刻全自动脉冲集尘器

现今工业吸尘器在很多领域中都有应用,工业吸尘器的发展将会越来越快,医药行业,电子行业,食品加工行业等。国家对医药行业的 GMP等级规定是硬性的。其中,一个重要的考核项目和指标便是清洁指标。工业集尘机是一种单机式滤筒除尘器,为立柜式箱形机体结构形式,而工业吸尘机因为其特殊功用,而成为医药生产性企业里不可省略的生产机械的一部分。

For some industries, such as electronics, mold manufacturing and other industries, industrial vacuum cleaner can effectively protect the environment of the production space, so effectively protect the quality of the product. Because the cleanliness of the production space of these enterprises directly affects the quality of their products, and even affects the qualified rate of products, so as to play an important role in reducing costs, improving the qualified rate of products and reducing the rate of bad products.

工业除尘器 在抛光、切割、打磨、粉碎、焚烧(燃烧)、等工业生产过程中,产生碎屑、烟雾、或者粉尘等微细颗粒物,通过除尘设备把这些微细颗粒物从气体中分离出来的过程为工业除尘的过程。除尘设备包括:吸尘罩、除尘管道、除尘器、风机等部分组成。吸尘罩:吸尘罩的形状与大小根据产尘点的大小和所需要的风速来决定,通常,吸尘罩需要尽量的靠近产尘点,吸尘罩的断面风速要足以克服颗粒物的重力和周围环境的风速,另外,吸尘罩的设计需要尊随两个原则,要把产尘点周围的粉尘浓度降到不足以影响工人健康的浓度,第二、不妨碍工人的日常操作。第三、不引起安全事故(主要是对风速和断面大小的控制,当风速和断面大小足够的大时,可以把其周围的轻质物体吸尽吸风管道)。

Nowadays, industrial vacuum cleaners are applied in many fields. The development of industrial vacuum cleaners will be faster and faster, such as the pharmaceutical industry, electronic industry, food processing industry and so on. The GMP grade regulation of the country is rigid to pharmaceutical industry. Among them, an important assessment project and index is clean index.

激光雕刻全自动脉冲集尘器

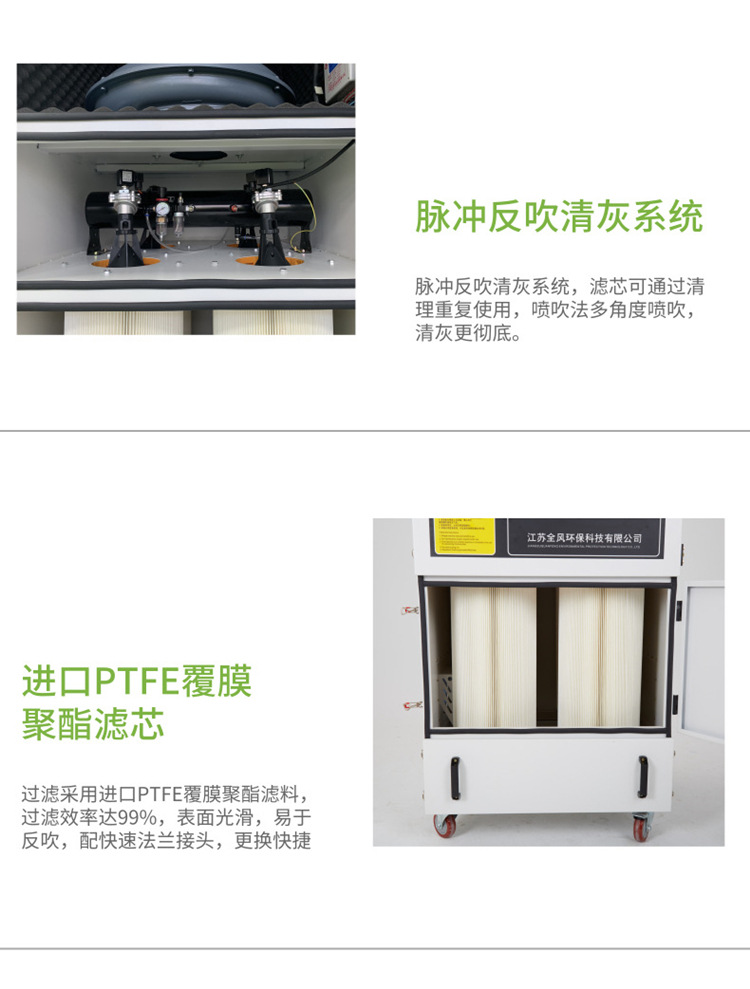

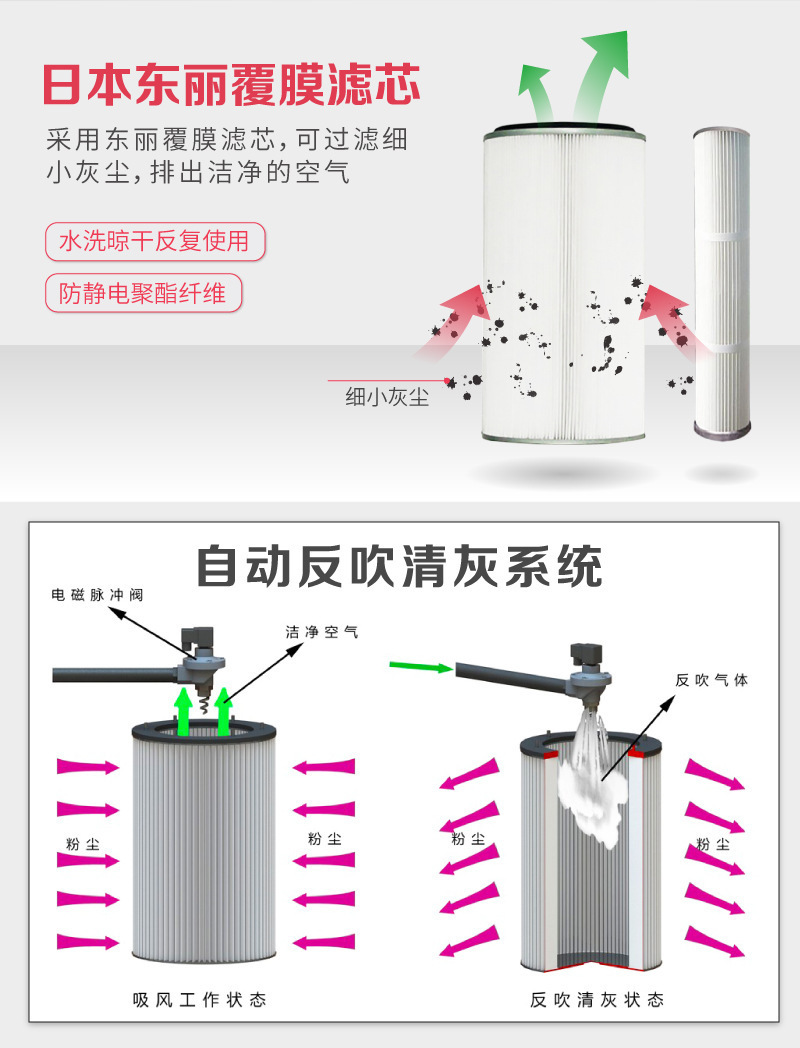

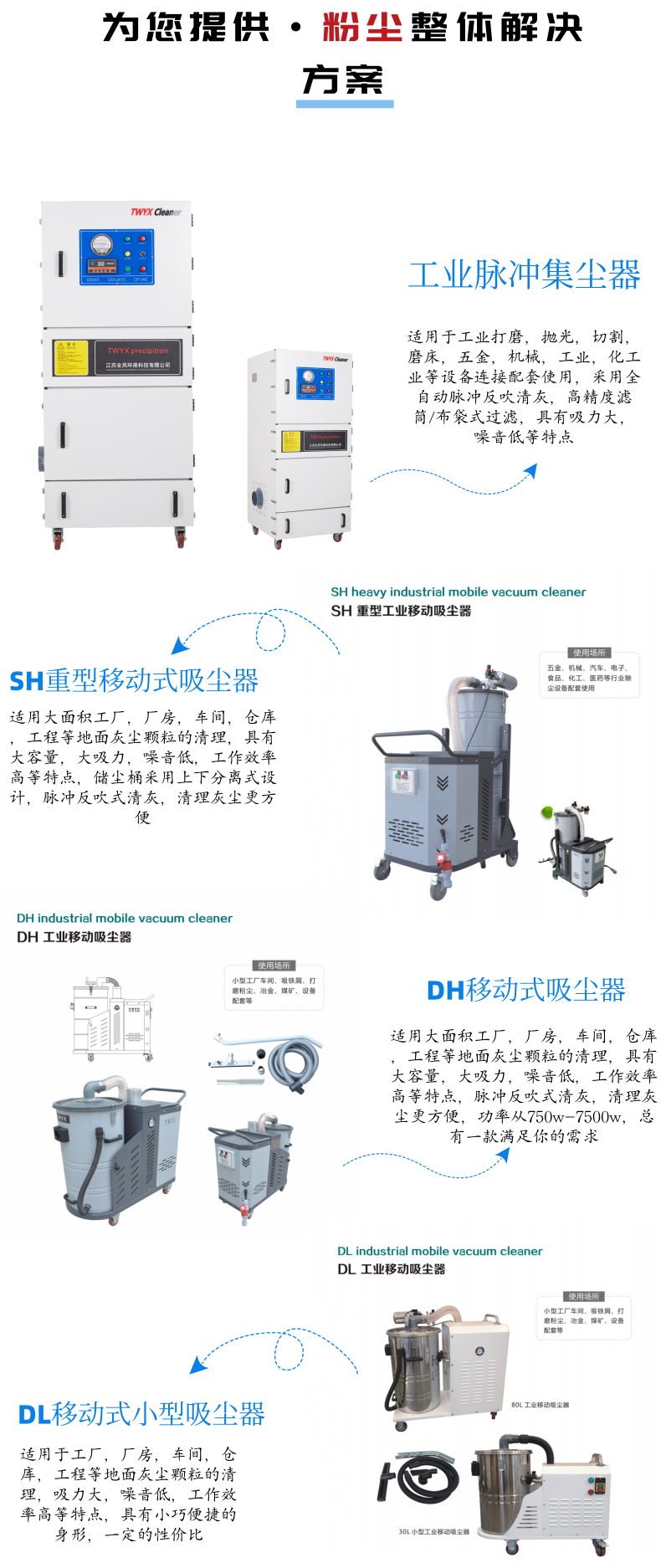

全自动脉冲喷吹清灰方式,经济型清灰方式, MCJC系列产品以外形美观、大风量、脉冲反吹清灰为特点,主尘隔及布尘袋双重过滤装置,可有效过滤99.99%之0.5um的粉尘,采用一体化柜式结构,外形美观,专为粉体行业、化工行业、金属加工行业、木工家具行业等漂浮粉尘而设计,。缺相保护,超远距离遥控控制,大功率负载,配置中国台湾透浦式引风机,日本东丽聚酯纤维滤筒,别的过滤精度和效率。

The vertical combined structure is adopted, which is composed of push-pull drawer type dust storage, filter cartridge dust removal, pulse jet dust removal and air outlet. The dust collection effect is 99.5% in an economic way. The modular combined design can be determined according to the user space. The power of the dust collector ranges from 0.75 kW to 22 kW. It is equipped with a secondary filtration system. The advanced plunger explosion back cleaning system is applied to optimize the back cleaning and a variety of filter materials, It can be applied to the collection of various smoke and dust.