水处理天通污水处理大连市水处理工程方案

-

≥ 1000台¥1.00

市政污水处理工程案例(缺氧+传统活性污泥法)

某污水处理厂是大连市修建的一座大型污水处理厂。该厂的建设引进关键技术、监控装置和设备,提高污水处理效率,充分利用生物能,节约能耗,节省用地,降低工程造价和运行成本。

该污水处理厂的工艺设计,在进行各种工艺方案比较的基础上,仍选用鼓风曝气的设计方案。其理由是大型污水处理厂采用鼓风曝气工艺管理简便、运行可靠。该污水处理厂肖化吸收了国外的技术,对每个单项构筑物及污水、污泥处理的细部方案都作了改进,如进水泵房及污水量计量的自动控制、洗砂排砂、排泥浓度控制、溶解氧白控、脱氨反硝化工艺、二沉池出水槽新工艺、消化池投泥方式、大型消化池的沼气搅拌、沼气发电升压联网、沼气锅炉及排泥阀、可调堰、细格栅等技术都在该厂得到了应用。

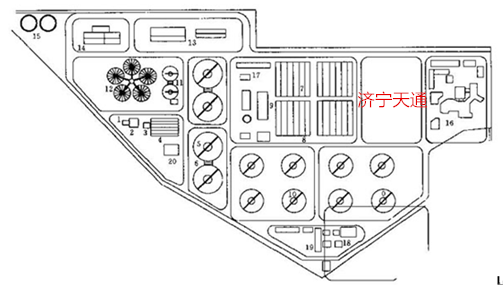

该厂污水处理系统分4个系列,4个圆形初沉池排成一行,4个曝气池组成田字形,8座二沉池设在厂区南侧,临近北塘排水河,使处理出水可就近排人河道。污泥处理区设在厂的西北角,5个消化池组成梅花形,污泥处理的控制室设在5个捎化池的中央。北侧设有两个沼气储罐、污泥脱水机房和沼气发电机房等。

处理构筑物及设备

格栅是污水处理厂的道预处理设施。该厂设6台垂直格栅,由计算机程序控制。高水位时格栅清污机将连续工作,运送格栅拦截的浮渣的皮带运输机与格栅清污机联锁运行,在所有格栅停止工作后,皮带运输机仍将继续运行一段时间。

泵房设有6个控制水位,控制5台泵的运行。为避免个别水泵负荷偏重而反复起动,水泵将依次循环投人运行。当某台泵因故障停止工作时,另一台泵将自动投入运行。

曲面格栅设在沉砂池的端部。每台格栅的清污动作根据水位模拟信号由计算机控制。当水位差处于正常值时,清污工作将按设定时间动作;当前后水位差超过设定值时,清污工作将连续进行。如果清污工作连续操作时间过长,计算机将发出报警信号。

曲面格栅刮出的浮渣落在皮带运输机上,皮带运输机的运行与格栅清污机联锁,清污工作停止后,运输机仍将运行一段时间。

沉砂池

曝气沉砂池设有6条廊道,每条长30m、宽4m、深4.3m,水力停留时间约6min。

池内设有振动空气(VIBRAIR)曝气器。全池设两座吸砂工作桥,负责3条廊道的吸砂。污秽的砂水被提升到洗砂槽,经搅拌后,有机物随洗砂水流回进水泵房,砂水被送至分砂机进行进一步脱水。分砂机设在进水泵房的上部建筑顶层,以便脱水的砂粒流入砂斗运走。

吸砂工作桥用行程开关控制,其上设有刮渣设施,以清除池内浮渣。空气提砂装置要求注续工作,由计算机控制。当空气压缩机发生故障时,备用机可自动投入。空气压缩机、分砂机和泵的运行状态由计算机监控,如出现故障将自动报警。

设有周边驱动全桥式刮混机的辐流式沉淀池 初沉池运行的关键是排泥,4座池轮流排泥的程序由计算机控制。每个排泥阀靠频率/时间自动操作。其功率/时间将根据计算机监测到的污泥浓度和流量束进行调整。排泥阀分两部分,启用的是电动阀门,排泥口用的是可手动调节的升降阀,该阀属非标设备。

为防止排泥系统出现堵塞故障,在两座初沉池间设一座污泥泵房。安装GF单螺杆泵4台,两座泵房共装8台污泥泵。污泥泵按频率邝j问自动操作,并由计算机进行调整,两座污泥泵房交替运行,在泵房的出口处设有污泥浓度模拟测量装置,污泥进人浓缩池前进行

流量检测。这些信号进入计算机后,将用于计算污泥的排放量,以调整排泥技术上频率和排混的持续时间。

济宁天通是一家水处理设备生产和销售集一体的公司,公司拥有高的技术人才,拥有高素质的工作团队,可以及时地为客户提供完善的售后服务。我公司主要产品:水处理设备,污水处理设备、废水处理设备、工业污水设备、农业废水设备、雨水净水设备、医院污水设备、钢厂废水设备、屠宰场废水设备、食品厂废水处理设备等多种设备,可根据要求定制水处理设备。

Municipal sewage treatment works (hypoxia + traditional activated sludge method)

A sewage treatment plant is a large sewage treatment plant built in dalian. The construction of the plant introduces key technologies, monitoring devices and equipment to improve the efficiency of sewage treatment, make full use of the energy of biomass, save energy, save land, reduce project cost and operation cost.

The process design of the wastewater treatment plant is based on the comparison of various process schemes, and the design scheme of air blast aeration is still selected. The reason is that the large sewage treatment plant is simple and reliable. The sewage treatment plant XiaoHua absorbed foreign advanced technology, for each single structure and detailed scheme of sewage and sludge treatment were improved, such as feed water pump house and the automatic control of sewage quantity measurement, washing sand sand, mud concentration control, white accused of dissolved oxygen, ammonia denitrification technology, new technology of the second pond, the water tank, the digester throw mud way, large biogas digester of stirring, biogas power generation booster networking, biogas boiler and mud valve, adjustable weir, fine grille and other advanced technology have been applied in the factory.

Four series are the factory sewage treatment system, four round pond, line, at the beginning of four aeration ChiZu narita glyph, eight the second pond is located in the south area of the plant near the north river, pond drainage treatment, water can row to the nearest river. The sludge treatment area is located in the northwest corner of the factory, and the five digesters form the plum blossom shape, and the control room of sludge treatment is in the center of 5. There are two biogas storage tanks, sludge dewatering machine room and biogas generator room.

Deal with structures and equipment

Grille is the first pre-treatment facility for sewage treatment plants. The factory has 6 vertical grille, controlled by computer program. High water level grille decontamination machine will work continuously, carrying grille intercept the scum of the belt conveyor with interlocking operation grille decontamination machine, after all the grille to stop working, belt conveyor will continue to run for a period of time.

The pump room has 6 control water level, control the operation of 5 pumps. In order to avoid the repeated starting of individual pump load, the water pump will be circulated in turn. When a pump fails to work, another pump will be automatically put into operation.

The curved grille is located at the end of the sink. The cleaning action of each grille is controlled by computer according to the water level simulation signal. When the water level is at the normal value, the cleaning work will be determined by the setting time; When the current water level difference exceeds the set value, the cleaning work will be carried out continuously. If the clean-up operation is too long, the computer will send an alarm signal.

The scum of the curved grille falls onto the belt conveyor, the belt conveyor runs with the grille cleaning machine interlock, the transport plane will still run for some time after the decontamination work stops.

Grit chamber

There are 6 corridors in the aeration and settling pit, with each length 30m, 4m wide and 4.3m deep, and the water retention time is about 6min.

The tank has a vibrating air aerator. There are two sand suction work Bridges in the whole pool, which is responsible for the sand absorption of three corridors. The polluted sand water is hoisted to the washing trough. After stirring, the organic matter comes back into the inlet pump room with the washing water, and the sand water is sent to the sander for further dehydration. The sand control machine is located at the top of the upper building of the inlet pump room so that the sand can be transported by the sand.

The sand suction work bridge is controlled by the travel switch, which has the slag removal facilities to remove the dregs in the tank. The air lifting device requires the injection of continuous work, controlled by computer. When the air compressor fails, the standby machine can automatically input. The operation state of air compressor, sand separating machine and pump is monitored by computer.

The key to the operation of the radial sedimentation tank of the surrounding drive full bridge type scraping mixer is the sludge discharge, and the computer control is the procedure for the four pools rotating the mud. Each dredge valve operates automatically by frequency/time. The power/time will be adjusted according to the concentration of sludge and the flux of the monitor. The dredge valve is divided into two parts, and the electric valve is enabled. The discharge valve is a manual adjustable lift valve, which is a non-standard equipment.

A sludge pump room was established between two initial sinks to prevent the sludge system from being blocked. Installation GF single screw pump 4, two pump room with 8 sludge pump. Sludge pump according to the frequency of kuang j q automatic operation, and adjusted by a computer, two sludge pump room, alternately in the pump room is equipped with the sludge concentration at the exit to simulate measurement device, sludge thickener in before

Flow detection. These signals will then be used to calculate the amount of sludge emitted by the computer to adjust the duration of the frequency and mixing of the sludge.

Jining day pass is a set of water treatment equipment production and sales of the company, the company has sophisticated technology talented person, has a high quality work team, can provide customers with perfect after-sales service in a timely manner. My company main products: water treatment equipment, sewage treatment equipment, wastewater treatment, industrial wastewater, agricultural wastewater, rain water purification equipment, hospital sewage equipment, steel plant waste water equipment, slaughterhouse wastewater treatment equipment, food factory waste water treatment equipment and other equipment, can professional custom according to the water treatment equipment.